Everything You Need To Know About Sensor Housing

Sensors play a crucial role in collecting critical data in the world of scientific measurement and industrial monitoring systems. However, a sensor’s reliability and lifespan

# Type at least 1 character to search # Hit enter to search or ESC to close

No products in the cart.

No products in the cart.

Product Categories

Advanced industrial water quality monitoring is critical for process optimization, regulatory compliance, and equipment protection, providing real-time insights, multi-parameter tracking, and system integration that save time and reduce cost, downtime, and operational risk.

Water quality monitoring in industrial settings has transitioned from a bit of paperwork to becoming an operational necessity. With industries coming under ever greater pressure to improve efficiencies, keep costs to a minimum, and comply with stricter environmental controls, the demand for advanced, robust monitoring solutions has never been greater.

Whether you are responsible for a factory floor, a treatment plant, or overseeing a food processing plant, knowing the basics of industrial water quality monitoring can be the difference between maintaining operational efficiency and incurring expensive fines.

Industrial water quality monitoring is not only about complying with regulations (though this is crucial!). Modern industrial facilities depend on well-controlled water quality for the protection of costly equipment, product uniformity, reducing pollution, and process efficiency. One missed monitoring event can lead to equipment failure, a halt in production, or regulatory non-compliance and could cost your company thousands of dollars.

Just think of all the complexity in modern industrial water systems. They encompass various source waters, multiple treatment techniques, differing requirements for different uses, and adherence to the correct procedure. Such complexity calls for a type of monitoring solution able to manage multiple parameters at the same time, while ensuring reliability and accuracy, as required for industrial operations.

One of the key concerns in industrial monitoring of water quality is multi-parameter monitoring. Although a single measure of water quality is convenient, industrial processes rarely rely on just one. Instead, water quality is determined by a combination of parameters.

It is still the case that pH monitoring is a key requirement in almost all forms of industry. Ranging from simply preventing cooling system corrosion to enhancing the efficiency and longevity of chemical processes. But pH only provides a fraction of industrial water quality.

Oxidation-Reduction Potential (ORP) is also an essential parameter for water that reflects its oxidizing or reducing capacity, and is therefore necessary information in the study of the effectiveness of disinfection and chemical treatment. Used in conjunction with pH monitoring, ORP provides a more comprehensive water picture than pH monitoring alone.

Dissolved oxygen (DO) relates to many aspects. For example, in a steel mill, DO helps measure corrosion rates and biological treatment processes. Excessive oxygen can promote corrosion, and insufficient oxygen can undermine biological treatment processes or suggest pollution problems.

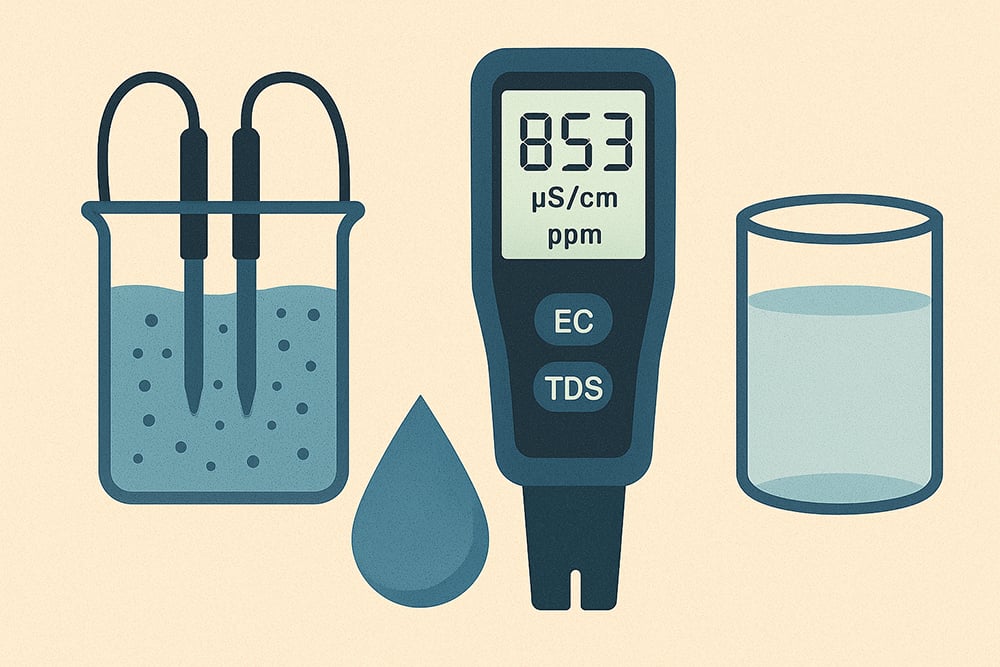

Total dissolved solids are what EC measures, which in turn informs an operator about the purity of a water source and can be indicative of contamination. It is crucial in applications of ultra-pure water and for discharging water quality monitoring.

Temperature control through RTD sensors is another added feature that assures that all other measurements are correct through accurate temperature compensation and directly provides actual process control data.

The difficulty is not so much in tracking each of these parameters separately, but instead in understanding their interconnections and preserving a consistent level of accuracy for all these measurements at any given time.

When water quality issues arise, industrial operations cannot afford to wait for water quality test results. Real-time monitoring with instant response to changes helps avoid minor issues that become big troubles. This is especially important in operations that are heavily affected by poor water quality or that affect the safety and cleanliness of equipment and operators.

Today’s industrial monitoring systems are delivering better, instant insight into real-time status. Operations need to be able to look not only at current numbers, but at the trend and see what’s coming before it becomes an issue. That demands monitoring systems with intuitive interfaces that can turn complex data into understandable, bite-sized formats.

Being able to provide a quick response to changing conditions is typically predicated on having in place a monitoring network that is integrated with wider process control systems. This inclusion offers an automated reaction to water quality variations, minimizes human error, and maintains uniform and consistent transit times.

Industrial water treatment monitoring units are only as good as their levels of calibration and accuracy. Under laboratory conditions, the careful calibration procedure can be sustained for a controlled working environment and staff. Industrial settings put forth some special demands: temperature changes, electrical interference, vibration, and poor accessibility for carrying out the maintenance.

Quality industrial sensing demands systems built for the field, yet possessing laboratory precision. That includes durable calibration methods that can be taken into the field, temperature compensation that adjusts to variations in environmental conditions, and sensors that deliver reliable performance even under harsh conditions.

The actual process of calibration needs to be user-friendly enough to be carried out consistently by operational staff. The complicated calibration method is likely to induce errors, which can result in inaccurate measurements if the maintenance frequency is not sufficiently high.

Industrial environments are naturally harsh. In addition, water quality monitoring equipment is subject to temperature extremes, moisture, vibration, electrical noise, and possible contact with chemicals.

IP67 enclosure ratings are the lowest acceptable level of protection for industrial water monitoring products, which includes limited entry of dust and resistance to short-term immersion in water. Despite the baseline rating, these products are rugged, surpassing simple environmental protection, a high-strength body, and quality accessories, thanks to its body design that withstands the impact of large machinery.

Modular design can be very beneficial for industrial applications. Maintenance is also made easier, and downtime is reduced when parts can be replaced or upgraded with little effort. This modularity also makes it possible to reconfigure the system, taking into account new control capabilities or monitoring needs, without total replacement.

Modern industrial plants have control systems that use multiple processes and systems. Water quality monitoring has to be fully integrated with current SCADA systems, process controllers, and data management systems.

Flexible output should be supported for such integration. In some applications, an analog 4-20 mA signal is necessary to connect to process controllers directly; in others, serial data communication is desirable so that the data can be more effectively used. The best supervision solutions offer numerous outputs so that they can be included in a variety of system topologies.

Serial communication protocols such as RS-232 can support more advanced data exchange, allowing monitoring systems to report on measurement quality, calibration status, and performance. This capability for intensive communication is the basis of more intelligent process control and predictive maintenance.

Vast quantities of data are captured from industrial water quality monitoring; however, raw data is of little use on its own. The recording, storage, and analysis of data over long periods allow for the identification of long-term trends and seasonal characteristics, which can then be optimized.

With time-stamped recording of data, you can establish correlations between water quality and system operation to troubleshoot cause and effect of quality problems and to improve treatment. This historical information is invaluable when it comes to regulatory reporting, process optimization, and troubleshooting.

SD card recording is a convenient solution for industrial applications, offering on-site, local storage that does not rely on access to network-attached or cloud-based resources.

The Atlas Scientific Industrial Sensor Interface Kit is specifically designed with the farming, agriculture, aquaculture, and brewing industries in mind. This solution meets all the important points listed above with careful engineering and commercial quality construction.

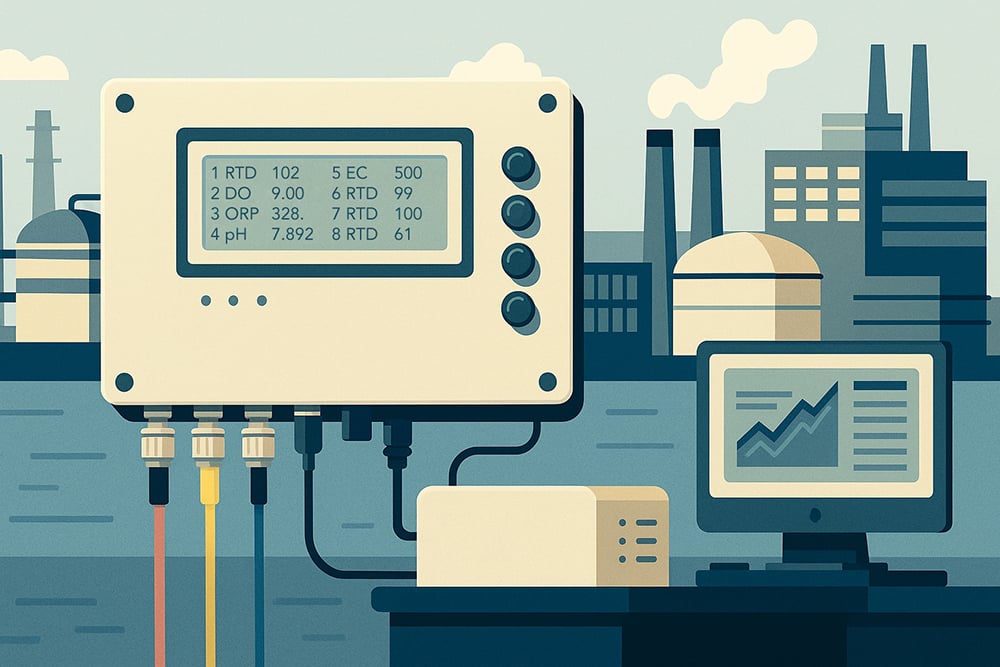

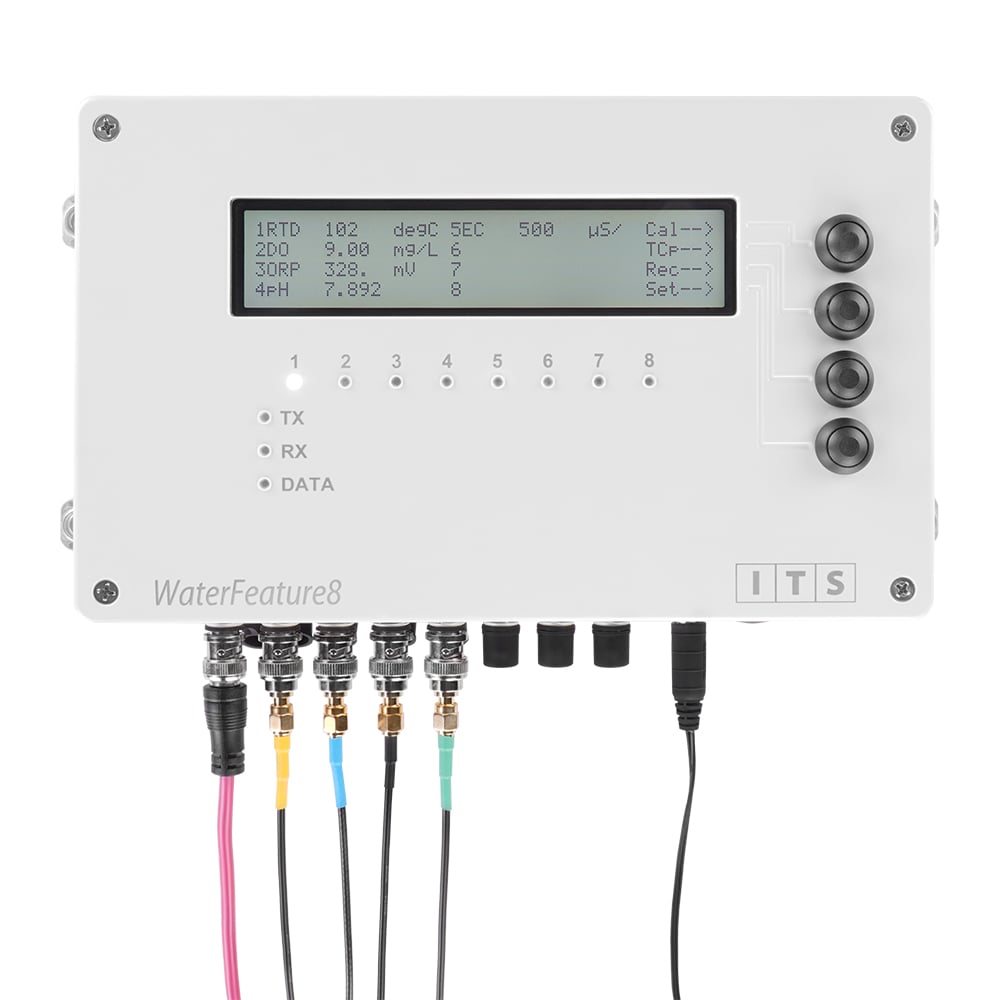

With its capability to monitor a maximum of eight sensors at once, this instrument fulfills the multi-parameter monitoring requirement of industrial applications. With pH, ORP, DO, EC, RTD, Flow, CO2, O2, pressure, and humidity sensors supported, the system provides a versatile monitoring solution within one platform.

A 4×40-character LCD shows live values, so users can instantly see what’s happening. The easy-to-use menu system allows on-site calibration and temperature compensation. Additionally, it offers the flexibility for on-site calibration services and repairs, eliminating the need to return the unit to the factory for calibration.

The modular design concept of the system enables operators to furnish the system with the sensor variety that is needed for their application. Whether it’s from simple monitoring demands to complete multi-parameter monitoring, the unit will meet today’s needs and tomorrow’s expanding demands.

Data output versatility enables user integration with almost any PLC, DCS, or PAC. Both 4-20mA analog outputs and RS232 serial communications allow for easy integration with existing systems, allowing for enhanced data management and process control capability.

IP67-rated enclosure delivers industrial-grade environmental protection, and rugged design enables high reliability in harsh industrial environments. This long life, together with the modular concept, means low maintenance and high uptime. The use of an SD card for time-stamped data recording enables you to store your data locally and transfer it for further analysis and reporting with ease. This capability is being used to achieve both regulatory compliance and process optimisation goals.

The approach to industrial water quality checking has gone from a simple ‘compliance-ticking’ exercise to a ‘mission-critical’ operational requirement. As operations become increasingly complex and rules increasingly stricter, an industrial sensor monitoring system pays for itself through more efficient processes, fewer equipment failures, and legal compliance.

Time to take water monitoring to the next level? Get in touch with the world-class team at Atlas Scientific today to find out how our line of industrial-grade products can change the way your factory measures everything.

Sensors play a crucial role in collecting critical data in the world of scientific measurement and industrial monitoring systems. However, a sensor’s reliability and lifespan

Advanced industrial water quality monitoring is critical for process optimization, regulatory compliance, and equipment protection, providing real-time insights, multi-parameter tracking, and system integration that save

Notifications