Best pH Probes For Hydroponics in 2025 – A Complete Buying Guide

Finding the best pH probe for hydroponics can make or break your growing success. In hydroponics, maintaining the correct pH is essential because it directly

# Type at least 1 character to search # Hit enter to search or ESC to close

No products in the cart.

No products in the cart.

Product Categories

Dissolved oxygen (DO) is essential in hydroponic systems to support root respiration and maintain plant health. Without soil aeration, plants rely on oxygen dissolved in the nutrient solution for growth and nutrient uptake. High DO levels prevent anaerobic conditions that can cause root rot, fungal infections, and harmful bacterial growth. This simple yet critical factor supports robust, sustainable hydroponic operations.

Dissolved oxygen (DO) is the hidden lifeline of hydroponic systems, as vital to plants as blood is to humans. While growers often focus on nutrients and pH, optimal oxygen levels in the water can make the difference between thriving crops and failing harvests. Think of DO as your plants’ underwater breathing system – it powers nutrient uptake, strengthens root health, and creates a shield against devastating diseases like root rot.

So, whether you’re growing microgreens or managing a commercial facility, mastering dissolved oxygen management is the key to unlocking your system’s full potential and achieving exceptional yields.

Dissolved oxygen refers to the number of oxygen molecules (O2) that are dissolved directly in water. Just as fish need oxygen to breathe underwater, plant roots require dissolved oxygen to perform essential metabolic processes.

Oxygen can enter water through several mechanisms:

Temperature plays a crucial role in how much oxygen water can hold. Cold water has a higher capacity for dissolved oxygen compared to warm water, which is an important consideration for hydroponic systems operating in different climates or seasons.

In hydroponic cultivation, dissolved oxygen takes on additional significance compared to traditional soil growing. In soil, roots can access oxygen through air pockets between soil particles. However, in hydroponic systems, roots are either partially or fully submerged in a nutrient solution, making dissolved oxygen their primary oxygen source.

The relationship between water and oxygen in hydroponics is complex and dynamic. Water molecules (H2O) contain oxygen, but this bound oxygen is not accessible to plant roots. Instead, roots require molecular oxygen (O2) dissolved within the water to perform cellular respiration and other critical metabolic functions. This dissolved O2 exists in the spaces between water molecules and can be measured in parts per million (ppm) or milligrams per liter (mg/L).

In hydroponic systems, several factors affect DO levels:

The importance of dissolved oxygen in hydroponic systems cannot be overstated. Let’s explore each critical aspect in detail:

Root health serves as the foundation for overall plant vitality, and dissolved oxygen plays a central role in maintaining healthy root systems:

Cellular Respiration & Energy Production

Root cells require oxygen for aerobic respiration, which produces ATP (adenosine triphosphate) – the energy currency of cells. Without adequate DO, roots cannot generate enough energy to power essential functions like:

Root Zone Architecture

Proper DO levels encourage:

Water & Nutrient Uptake Mechanics

Oxygen is essential for:

Adequate dissolved oxygen levels create an environment that actively suppresses pathogen development:

Direct Pathogen Suppression

High DO levels help prevent disease by:

Pythium Prevention

Pythium, a particularly troublesome pathogen in hydroponics, is significantly affected by DO levels:

System Health

Maintaining appropriate DO levels contributes to overall system health by:

Dissolved oxygen plays a crucial role in nutrient uptake through multiple mechanisms:

Active Transport Systems

Proper DO levels support:

Root Zone Chemistry

Oxygen influences nutrient availability by:

Nutrient Absorption Efficiency

High DO levels improve:

Dissolved oxygen impacts overall system functionality:

Water Quality

Proper DO levels maintain water quality by:

Nutrient Solution Stability

Oxygen helps maintain stable growing conditions through:

System Efficiency

High DO levels improve:

Understanding DO probe technology and proper measurement techniques is crucial for successful hydroponic cultivation. Modern dissolved oxygen probes utilize sophisticated electrochemical or optical sensing technologies to provide accurate measurements of oxygen levels in solution.

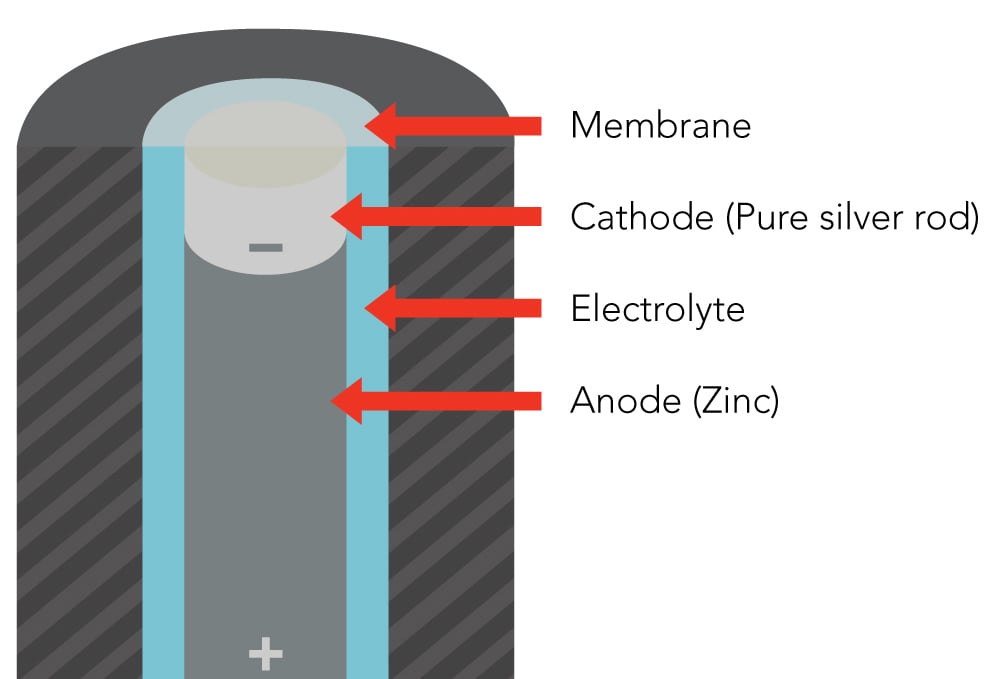

Electrochemical DO probes, also known as Clark-type sensors, operate on a galvanic or polarographic principle.

These probes contain:

The measurement process occurs as follows:

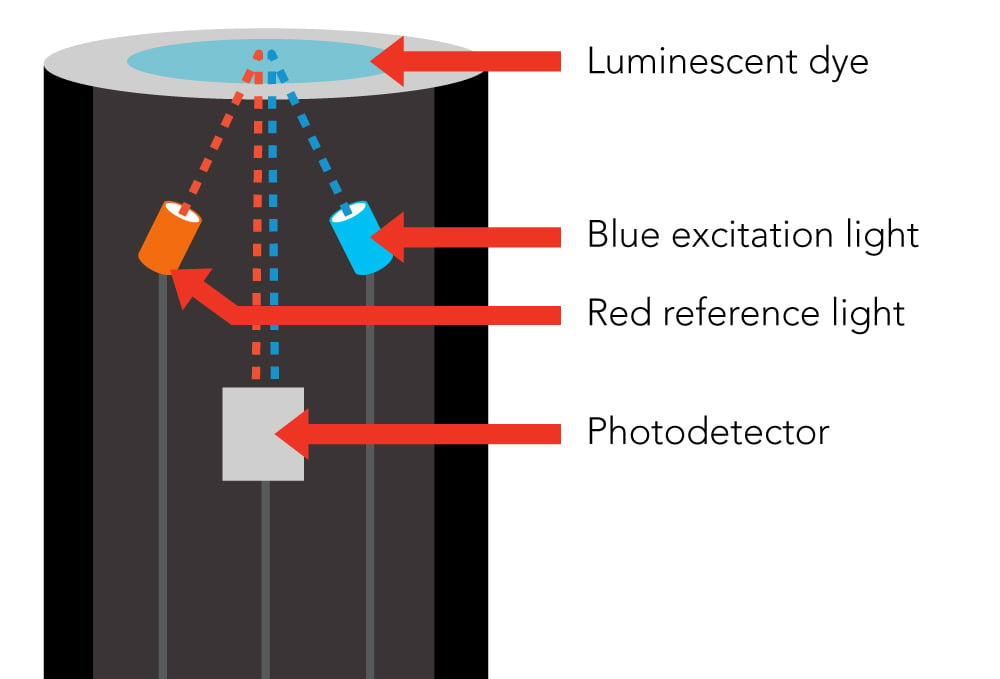

Optical DO probes, or luminescent dissolved oxygen sensors, use advanced optical technology:

Atlas Scientific’s DO Probes stand out for several key reasons:

Exceptional Accuracy:

Robust Design:

Smart Features:

Versatility:

Effective dissolved oxygen management requires a comprehensive approach that goes beyond simple monitoring and basic aeration. Here’s a detailed exploration of best practices for both commercial and hobby operations:

Commercial hydroponic facilities must implement systematic approaches to DO management that ensure consistent levels across large-scale systems. This begins with a comprehensive system design that incorporates multiple oxygenation methods and redundant monitoring systems.

Initial system design should include careful consideration of water flow patterns, ensuring adequate turbulence and mixing while avoiding dead zones where oxygen levels can drop. Pipe sizing and pump selection must account for both water delivery and oxygenation requirements. Integration of multiple aeration methods provides redundancy and ensures stable DO levels even if one system fails.

Staff training plays a crucial role in maintaining proper DO levels. Operators should understand the relationship between temperature, pressure, and dissolved oxygen solubility. They should be trained to recognize early signs of oxygen deficiency in plants and know appropriate corrective actions. Regular calibration of monitoring equipment and maintenance of aeration systems should be part of standard operating procedures.

Documentation and record-keeping are essential components of professional DO management.

Facilities should maintain detailed logs of:

Advanced commercial operations should implement automated control systems that continuously monitor DO levels and adjust aeration equipment accordingly. These systems can integrate with climate controls to maintain optimal conditions for oxygen solubility while ensuring energy efficiency.

Home hydroponic growers face unique challenges in managing dissolved oxygen levels, often working with smaller systems that can experience rapid changes in water chemistry. Success requires attention to detail and regular monitoring, even without access to professional equipment.

System design for hobby growers should focus on reliability and simplicity. Multiple small air stones often provide better distribution than a single large one. Regular cleaning of air stones and supply lines prevents clogging and ensures consistent performance. Water temperature management becomes particularly important in home systems, which may be more susceptible to ambient temperature fluctuations.

Daily observation of plant health serves as an important monitoring tool for hobby growers. While professional DO meters may be cost-prohibitive, growers can learn to recognize signs of oxygen stress:

Maintenance routines should include weekly cleaning of aeration equipment, monthly replacement of air stones if needed, and regular inspection of air supply lines for kinks or blockages. Hobby growers should also maintain basic records of system changes and plant responses to help identify patterns and optimize their setup over time.

Scenario 1: Sudden DO Drop in NFT System

Initial Response

Investigation

Resolution

Scenario 2: Gradual DO Decline in DWC

Analysis

Remediation

Prevention

Scenario 1: Root Browning in Small DWC

Immediate Actions

Solutions

Future Prevention

Scenario 2: Poor Growth in Ebb and Flow

Diagnosis

Corrections

Ongoing Management

Dissolved oxygen management is a crucial aspect of successful hydroponic cultivation that deserves careful attention and regular monitoring. Whether operating a commercial facility or a hobby system, maintaining proper DO levels will significantly impact plant health, growth rates, and overall system success.

Understanding and managing dissolved oxygen levels is not just about preventing problems – it’s about optimizing your hydroponic system for maximum efficiency and productivity. With proper attention to this vital aspect of hydroponics, growers can achieve better yields, healthier plants, and more consistent results.

If you would like to learn more about DO in hydroponics, or which DO meter will best suit your needs, do not hesitate to reach out to the world-class team at Atlas Scientific.

Finding the best pH probe for hydroponics can make or break your growing success. In hydroponics, maintaining the correct pH is essential because it directly

The fastest way to reduce ammonia levels in a fish tank is to perform partial water changes, temporarily stop feeding fish, use chemical filtration, increase

Notifications