The Uses Of Water In Agriculture

Water monitoring is becoming crucial as agricultural droughts become more common and the global population rises, and solutions are needed to feed everyone with less

# Type at least 1 character to search # Hit enter to search or ESC to close

No products in the cart.

No products in the cart.

Product Categories

Measuring oil conductivity is crucial for ensuring system safety, preventing electrostatic discharge, and maintaining operational efficiency. It helps monitor oil quality, extend equipment life, and enhance safety in critical processes such as drilling, lubrication, and power generation.

In the world of industrial operations, the measurement of oil conductivity is often overlooked, yet it plays a pivotal role in ensuring system efficiency, safety, and longevity. From the depths of oil drilling operations to the intricacies of lubrication systems in turbines and hydraulic systems, understanding oil conductivity is essential to preventing costly damage and ensuring optimal performance.

In this article, we will explore what oil conductivity is, why it is crucial to measure it in various industrial processes, and how conductivity is measured and managed in different industries/sectors.

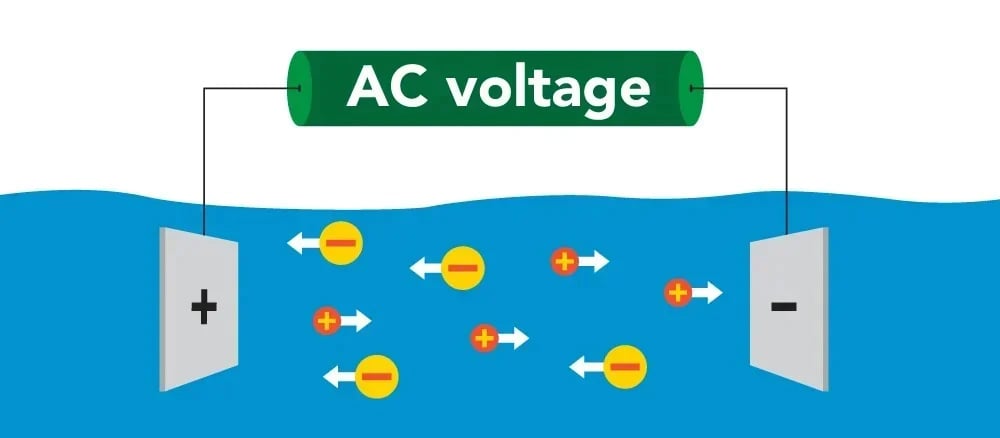

At its core, conductivity refers to the ability of a substance to conduct an electric current. This property is determined by the presence of mobile charged particles, or ions, within a material. In liquids, such as oils and lubricants, conductivity indicates how well the liquid allows electricity to flow through it. The more conductive a liquid, the easier it is for electricity to pass through, which is typically the result of dissolved ions or impurities within the fluid.

In the case of oils, conductivity is influenced by several factors, including:

The measurement of electrical conductivity is typically expressed in Siemens per centimeter (S/cm), or for oils, in picosiemens per meter (pS/m), and is a critical parameter in many industrial processes, especially where oils are used as insulators or lubricants.

The ability to measure oil conductivity is crucial across various industries for several reasons, including operational efficiency, equipment longevity, and safety.

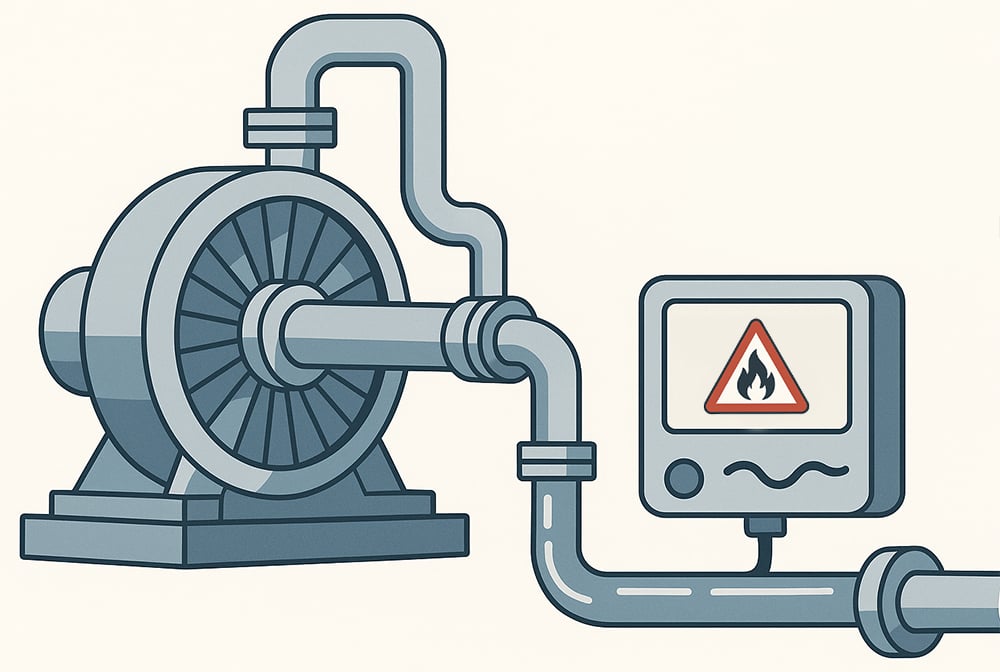

One of the most significant risks associated with low-conductivity oils is the potential for electrostatic discharge (ESD). As oils with low conductivity flow through pipes and equipment, they can build up static electricity due to friction between the oil and the surfaces it flows over. If the charge becomes too high, it can discharge suddenly, causing sparks or even fires. This is particularly dangerous in systems containing flammable liquids or gases.

Monitoring conductivity helps prevent these discharges by indicating when the oil’s conductivity is dangerously low. If oil conductivity falls below a critical threshold, adjustments can be made, such as adding anti-static additives or modifying system flow rates to reduce friction and charge buildup.

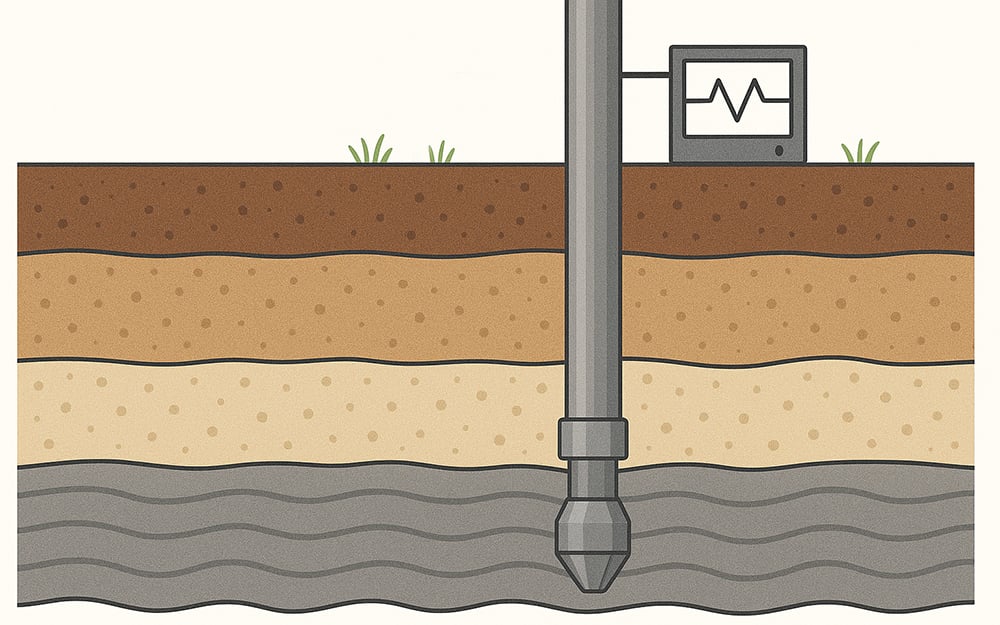

In oil drilling, conductivity measurement is used to monitor the properties of drilling mud (also known as drilling fluid). Drilling mud serves multiple purposes, such as cooling and lubricating the drill bit and carrying rock cuttings to the surface. Oil-based and water-based drilling fluids are often used depending on the geological conditions of the drilling site.

In water-based muds, conductivity measurements are vital for formation evaluation, as they can indicate changes in the subsurface rock formations. By assessing conductivity at different depths, geologists and drilling engineers can gain valuable insights into the nature of the rock and adjust the drilling process accordingly.

If conductivity measurements diverge significantly between the active pit and ditch sensors, this could signal a change in the geological formation, requiring a change in mud composition to maintain stability and avoid potential oil well/drill hole blowouts.

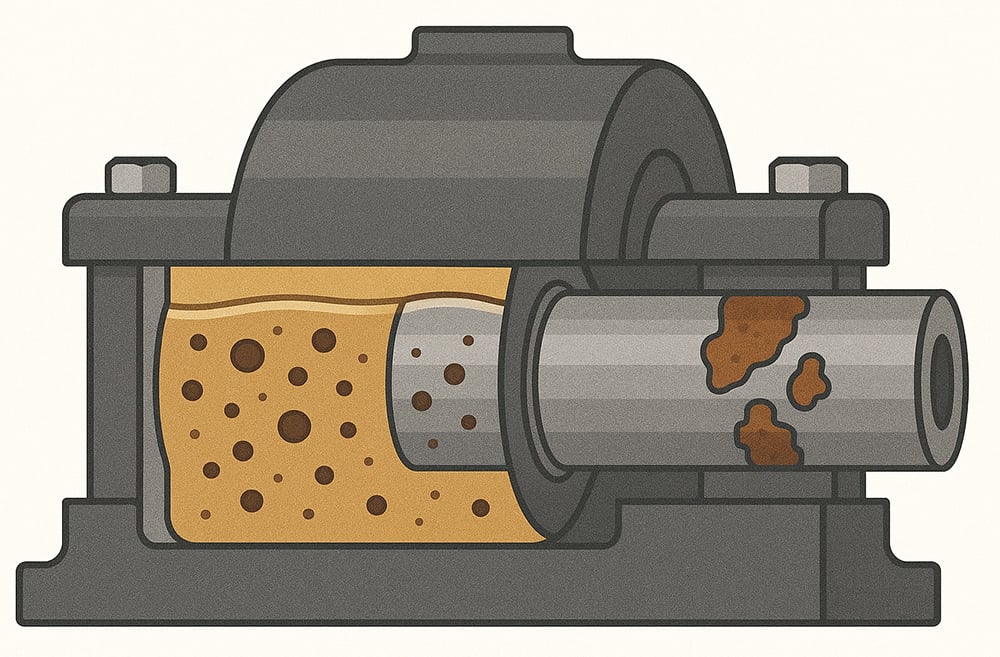

In lubrication systems, such as those used in turbines, hydraulic pumps, and industrial machinery, oil conductivity plays an essential role in protecting against electrostatic charging. Oils used in these systems are often lightly refined and are designed to be good insulators. However, over time, oils may accumulate metal particles, wear debris, or contaminants that alter their conductivity, potentially leading to corrosion and damage to components.

By regularly monitoring oil conductivity, maintenance teams can assess the health of the lubricant and detect potential issues before they result in costly downtime.

In turbines, for example, oils with low conductivity can create problems due to static electricity buildup. This can lead to sparks or even fires in extreme cases. By monitoring the conductivity of the turbine oil, operators can adjust the formulation to reduce the risks of ESD and enhance the overall safety of the system.

Conductivity measurements are also used in oil condition monitoring to assess the quality and health of lubricants in real time. As oils age, their conductivity can change due to oxidation, contamination, and breakdown of additives. Regular conductivity testing can provide early warnings of issues such as acid formation, moisture contamination, or the depletion of essential additives. By keeping track of oil conductivity, operators can take proactive steps to maintain oil quality and extend the service life of machinery.

The applications of oil conductivity measurements span various industrial sectors. Below are some key areas where oil conductivity plays a critical role.

As drilling progresses, mud logging helps engineers evaluate the drilling fluid and cuttings. Conductivity measurements in the drilling mud help assess the formation’s electrochemical properties and provide insights into the presence of hydrocarbons.

For example, if the conductivity in the drilling mud changes significantly, it might indicate the presence of a productive pay zone, suggesting that drilling should be focused on that specific area.

In addition, conductivity measurements help ensure the safety and efficiency of the drilling operation. By monitoring conductivity levels, engineers can detect sudden changes in mud characteristics that could lead to dangerous conditions like blowouts or wellbore instability.

Conductivity measurements in turbine oils and hydraulic fluids are crucial for maintaining safe operational conditions. Low-conductivity oils in turbine systems are particularly prone to ESD, leading to the risk of fire hazards or damage to sensitive components.

By monitoring the oil conductivity, engineers can ensure that static charges are kept under control, improving the safety and efficiency of the system.

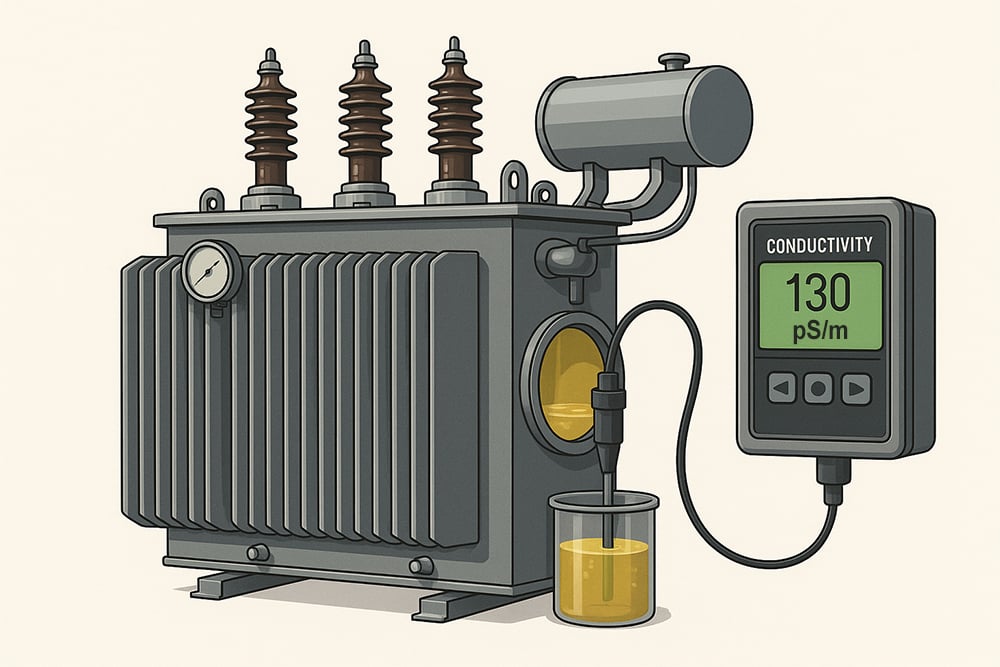

In power transformers and electrical insulation systems, oils are used as dielectric fluids. The dielectric strength of these oils is a key property that helps prevent electrical arcing and short circuits. Monitoring the conductivity of these oils allows engineers to assess whether the oil’s insulating properties are still within safe limits or whether the oil has degraded, requiring replacement.

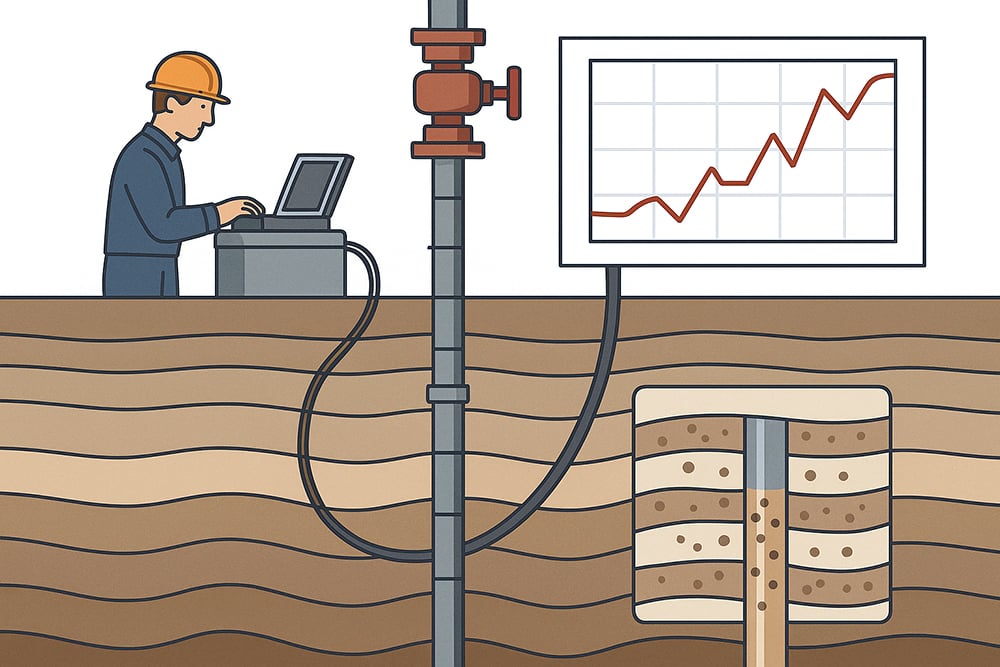

Measuring oil conductivity is generally done using two primary methods: manual measurements and continuous in-line monitoring.

In some applications, conductivity can be measured manually by immersing a conductivity meter probe with electrodes into a sample of oil. The conductivity probe applies a voltage across the oil and measures the current that flows through the liquid, which can then be converted into a conductivity reading. This method is typically used in laboratory settings or when periodic checks are required.

In industrial environments where constant monitoring is required, continuous in-line conductivity sensors are used (like the Industrial Monitoring Kit). These sensors are installed in the pipelines or tanks through which the oil flows. As oil passes through the sensor, the system continuously measures the oil’s conductivity, providing real-time data.

This method is particularly valuable for automated systems, allowing for immediate adjustments to be made if conductivity falls outside of the desired range.

Both methods are useful, depending on the operational requirements and the level of monitoring needed. Some advanced systems also use mobile conductivity measurement devices, allowing for flexible, on-the-go testing of oils in various industrial settings.

While measuring oil conductivity is crucial for many industries, there are challenges associated with accurate measurements. For instance, oils used in drilling operations often contain solid particles, mud, and contaminants, which can coat traditional conductivity sensors and render them unreliable. High-viscosity oils can also cause difficulties in achieving accurate readings, as the flow rate may be too slow to provide consistent results.

Recent advancements in sensor technology, such as thermal conductivity sensors and self-cleaning probes, have helped mitigate these challenges, allowing for more reliable and accurate measurements even in challenging conditions.

The conductivity of oil is directly linked to the likelihood of electrostatic charge buildup. Oils with lower conductivity tend to accumulate charge more easily as they flow through machinery or pipelines. This charge can discharge suddenly, causing sparks, which can damage equipment or lead to fires, especially in environments where flammable liquids are present.

By monitoring the conductivity of the oil, operators can ensure that it remains above a critical threshold, reducing the risk of electrostatic discharges. If the conductivity falls below the recommended levels, adjustments can be made, such as adding conductive additives or modifying system components to reduce the risk of charge buildup.

Measuring oil conductivity is an essential practice in industries that rely on oils for lubrication, insulation, or as part of their drilling processes. By regularly monitoring oil conductivity, companies can improve system safety, extend equipment life, and prevent costly failures due to electrostatic discharges or other operational issues.

In the future, as technology continues to evolve, the importance of oil conductivity monitoring will only increase, helping industries stay ahead of potential risks while optimizing their processes for greater efficiency and sustainability.

To learn more about oil conductivity or what conductivity meter will best suit your testing needs, do not hesitate to contact the world-class team at Atlas Scientific.

*Side note* Atlas Scientific Conductivity probes, are not rated for oil testing.

Water monitoring is becoming crucial as agricultural droughts become more common and the global population rises, and solutions are needed to feed everyone with less

The ways to reduce Total Dissolved Solids (TDS) in water are reverse osmosis (most common process, 90-99% removal of dissolved solids using a semi-permeable membrane),

Notifications