Best pH Probes For Hydroponics in 2025 – A Complete Buying Guide

Finding the best pH probe for hydroponics can make or break your growing success. In hydroponics, maintaining the correct pH is essential because it directly

# Type at least 1 character to search # Hit enter to search or ESC to close

No products in the cart.

No products in the cart.

Product Categories

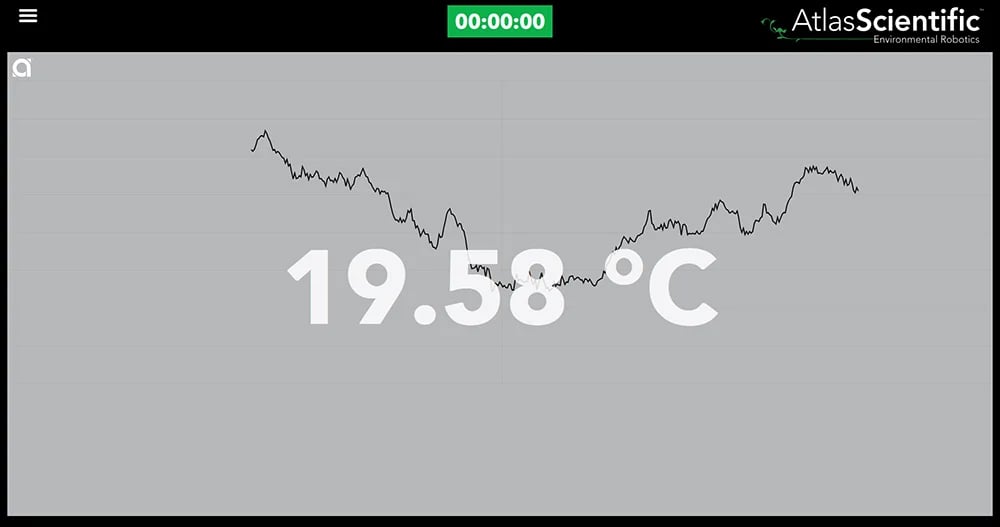

Laboratory temperature monitoring systems ensure accurate, consistent environmental conditions, essential for preserving sample integrity, optimizing experimental results, preventing costly equipment malfunctions, and maintaining compliance with regulatory standards.

In scientific research and quality control, precision is not just a goal—it’s absolutely essential. Among the many factors that contribute to maintaining a controlled laboratory environment, the accurate monitoring of temperature and humidity stands out as particularly crucial. These environmental parameters can profoundly impact the integrity of samples, the reliability of test results, and the overall efficacy of laboratory operations.

Temperature regulation is essential for numerous reasons. Many chemical reactions and biological processes are temperature-dependent, meaning that even slight fluctuations can significantly impact experimental outcomes. For example, enzymes have optimal temperature ranges for their activity, and deviations from these ranges can lead to inaccurate results in biochemical assays. Additionally, temperature control is critical for the proper functioning and longevity of laboratory equipment, such as analytical instruments and storage units for temperature-sensitive materials.

Humidity, while often overlooked, plays an equally critical role. High humidity can promote microbial growth, potentially contaminating samples or culture media. It can also accelerate the degradation of hygroscopic materials and affect the accuracy of gravimetric measurements.

In contrast, low humidity environments can cause static electricity buildup, which can be particularly problematic in labs working with sensitive electronic equipment or volatile compounds. Static discharge can damage equipment or even pose safety risks in labs handling flammable materials.

Temperature fluctuations can have far-reaching consequences on the physical and chemical properties of samples, potentially compromising research outcomes and product quality. Let’s explore some specific examples:

In drug development and quality control, temperature stability is paramount. Even slight temperature changes can affect drug stability, potency, and shelf life. For example, protein-based drugs are particularly sensitive to temperature fluctuations.

Temperature variations can dramatically influence bacterial growth rates. Most pathogenic bacteria grow optimally at 37°C, the human body temperature. A fluctuation of just a few degrees can accelerate or inhibit growth, leading to inaccurate colony counts or false negatives in diagnostic tests.

In forensic science, maintaining sample integrity is crucial for legal proceedings. DNA samples, for example, must be stored at specific temperatures to prevent degradation. The FBI’s Quality Assurance Standards for Forensic DNA Testing Laboratories mandate strict temperature controls for evidence storage.

In quality control labs for paper or textile industries, humidity significantly affects material properties. Changes in relative humidity can cause dimensional changes in paper, affecting print quality or packaging integrity.

Unlike manual checks, which provide only snapshots of environmental conditions, automated systems offer 24/7 monitoring. This continuous oversight ensures that no fluctuations go unnoticed, even outside of regular working hours.

For example, a freezer malfunction occurring over a weekend could be detected and addressed immediately, potentially saving valuable samples from degradation.

Advanced monitoring systems can send immediate notifications when parameters deviate from set ranges. These alerts can be customized to reach relevant personnel through various channels such as email, SMS, or even automated phone calls. This rapid response capability can be crucial in preventing catastrophic events.

For example, in a biorepository storing irreplaceable patient samples, a timely alert about rising temperatures could prompt immediate action, preserving years of research.

Automated systems maintain detailed logs of temperature and humidity data. This wealth of information can be invaluable for several reasons:

By automating environmental monitoring, lab personnel can focus on core research activities rather than manual checks. This not only increases productivity but also reduces the risk of human error in data recording.

While the initial investment in a monitoring system may seem significant, these systems can prevent costly sample loss and equipment damage in the long run.

Maintaining consistent environmental conditions is crucial for research reproducibility—a growing concern in the scientific community. By ensuring stable conditions across experiments, labs can eliminate one potential source of variability in their results.

While different types of laboratories have varying requirements for temperature and humidity control, some general standards are widely accepted:

General Laboratory Areas: Most laboratories aim to maintain a temperature between 20°C and 25°C (68°F to 77°F). This range is comfortable for personnel and suitable for most general lab equipment.

Cleanrooms: ISO 14644-1 standards for cleanrooms specify temperature requirements based on the cleanroom class. For example, Class 5 cleanrooms typically maintain temperatures between 20°C and 22°C with a maximum deviation of ±0.5°C.

Incubators: Biological incubators usually operate at 37°C to mimic human body temperature, with precision often required to be within ±0.1°C.

Ultra-Low Temperature Freezers: For long-term biological sample storage, temperatures are typically maintained at -80°C with a tolerance of ±5°C.

Metrology Labs: Temperature control is even more stringent in metrology labs. The National Institute of Standards and Technology (NIST) maintains some of its calibration laboratories at 20°C ±0.1°C.

General Laboratory Areas: The ideal relative humidity range for most labs is between 30% and 50%. This range helps prevent static electricity buildup while also inhibiting microbial growth.

Cleanrooms: Humidity control in cleanrooms is crucial. ISO 14644-1 standards often require humidity to be maintained between 40% and 60% RH, with specific requirements varying by cleanroom class.

Electronics Labs: Labs working with sensitive electronic components often maintain lower humidity levels, typically around 30-40% RH, to prevent static discharge.

Paper Testing Labs: TAPPI (Technical Association of the Pulp and Paper Industry) standards specify 50% ±2% RH for paper testing environments.

NOTE: It’s crucial to note that these are general guidelines. Specific standards may vary depending on the nature of research, regulatory requirements, and equipment specifications.

Selecting an appropriate temperature and humidity monitoring system is a critical decision that can significantly impact laboratory operations. Here are key factors to consider:

Accuracy & Precision

The system’s sensors should meet or exceed your accuracy requirements. For temperature, look for sensors with accuracy of at least ±0.5°C, with ±0.1°C being preferable for more sensitive applications.

For humidity, sensors with ±2% RH accuracy are typically sufficient for general lab use, while more sensitive applications might require ±1% RH accuracy.

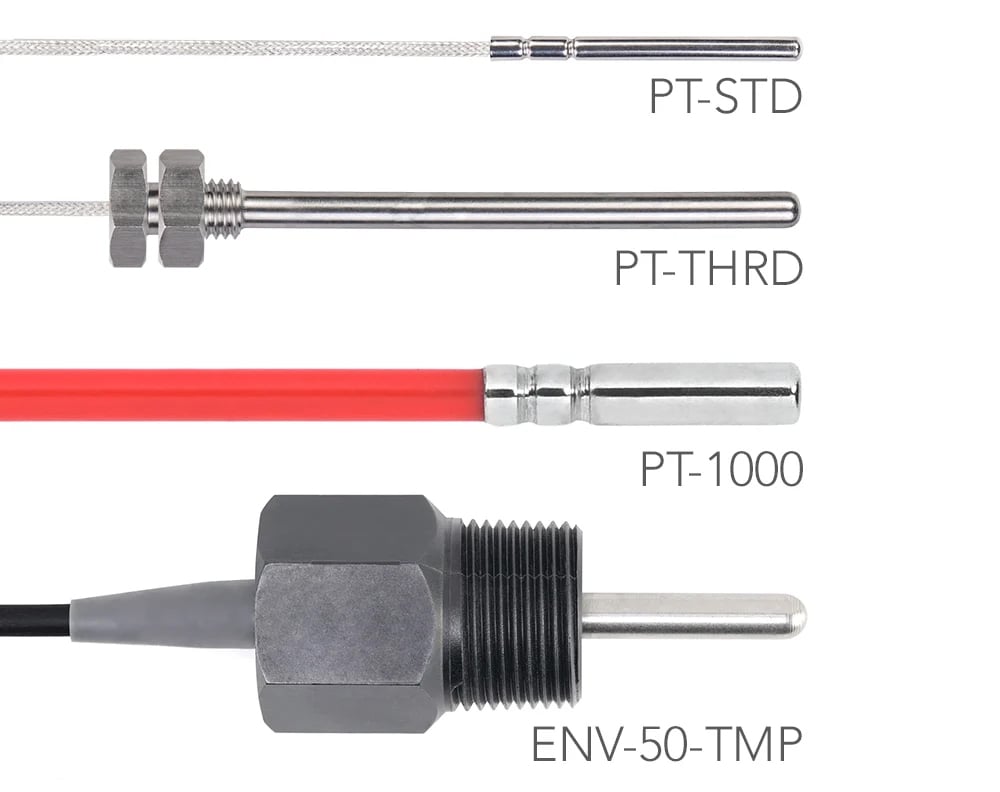

Atlas Scientific’s Temperature Probes & Sensors offer excellent accuracy and reliability for laboratory applications, with some models providing accuracy as high as ±0.1°C.

Range

Ensure the system can monitor the full range of temperatures and humidity levels you expect in your lab. This is particularly important for labs with diverse storage conditions, from ultra-low temperature freezers to incubators.

Calibration

Choose systems that are easy to calibrate and maintain their accuracy over time. Look for sensors that support NIST-traceable calibration. Some advanced systems offer self-calibration features or easy field calibration options.

Data Logging & Reporting

Look for systems that offer robust data storage and reporting features. Consider:

– Data storage capacity (local and/or cloud-based)

– Data export formats (CSV, PDF, etc.)

– Customizable reporting options

– Audit trail features for regulatory compliance

Alarms & Notifications

Ensure the system can alert relevant personnel through multiple channels when parameters are out of range. Look for features like:

– Customizable alarm thresholds

– Escalation procedures for unacknowledged alarms

– Remote alarm acknowledgment capabilities

Integration

Consider how well the system can integrate with your existing laboratory information management system (LIMS) or other software. API availability can be crucial for seamless integration.

Wireless vs. Wired

Wireless systems offer flexibility in sensor placement and can be easier to install, especially in existing facilities. However, wired systems may offer more reliability in environments with potential RF interference.

Power Backup

Look for systems with battery backup to ensure continuous monitoring during power outages.

Scalability

Choose a system that can grow with your lab’s needs. Modular systems that allow easy addition of new sensors or monitoring points can be advantageous.

In the precision-driven world of laboratory science, maintaining stable environmental conditions is not just beneficial—it’s essential. By investing in high-quality monitoring solutions, strategically implementing them, and following best practices, laboratories can enhance the reliability of their research, improve operational efficiency, and maintain the highest standards of scientific excellence.

If you would like to learn more about the types of temperature and humidity sensors that we offer for monitoring systems, do not hesitate to contact the world-class team at Atlas Scientific.

Finding the best pH probe for hydroponics can make or break your growing success. In hydroponics, maintaining the correct pH is essential because it directly

The fastest way to reduce ammonia levels in a fish tank is to perform partial water changes, temporarily stop feeding fish, use chemical filtration, increase

Notifications